MODULAR CONSTRUCTION

Modular construction is an architectural trend that the WARSS DESIGN team is very much promoting. Prefabricated modular houses are a novelty and are becoming increasingly popular. Our company offers houses in two different technologies. Those based on timber frame construction and those made of reinforced concrete in the panel and rib system.

Features of timber frame construction:

- low heat transfer coefficient U< 0.12 W/m2K Low U-value means that heat loss is very small which results in maintaining a constant temperature inside the building

thermal insulation - materials made of natural wood fibre The materials used in our technology effectively insulate the external walls and roof of the building in winter and protect against the sun’s rays in summer.

- the load-bearing structure is made of certified laminated wood LVL , BSH, KVH and I-beams; due to their exceptional strength properties, these materials are not subject to cracking or deformation, are resistant to damage and at the same time resistant to fungi and insects. Our energy-saving technology uses modern, lightweight timber constructions, which are characterised by excellent thermal performance, high strength and rigidity.

We manufacture the modules based on:

- KVH structural solid wood – four-sided planed and milled, properly dried, guaranteeing resistance to fungal and insect damage.

- LVL and BSH glued laminated timber – is not subject to deformation or cracking is characterised by a high level of fire resistance.

- I-beams – extremely rigid, guaranteeing dimensional stability, high thermal insulation and exceptional load resistance.

Features of the structure made of reinforced concrete in the ribbed panel system:

- high above-standard thermal insulation, a 36 cm wall achieves a heat transfer coefficient of U< 0.13 W/m2K

- low dead weight: for a 36 cm wall, the load-bearing capacity of 6 storeys is approximately 200 kg/m2

- good strength parameters, allows to reduce the thickness of external walls and thus increase the usable area

- flexibility and accuracy of wall formation, factory prefabrication

- lower interior finishing costs, there is no need to plaster the internal walls

- reduced execution time, on average by 50%cost-effectiveness

- lowest carbon footprint

- possibility to install the 3Thermo underfloor heating system

Construction cross-section:

- C30/37 concrete

- EPS80 insulation

- 3 Thermo radiator

- Glue-in mesh

- Elastolich cladding

WARSS DESIGN’s team of architects designs bespoke modular homes and fabricates and builds turnkey homes. Our partners manufacture bespoke modules and assemble the finished elements with interior finishes.

Single-family homes, multi-family homes and public buildings, schools, senior citizens’ homes, kindergartens, hotels and tourist facilities.

WARSS DESIGN has a team overseeing and coordinating the construction process.

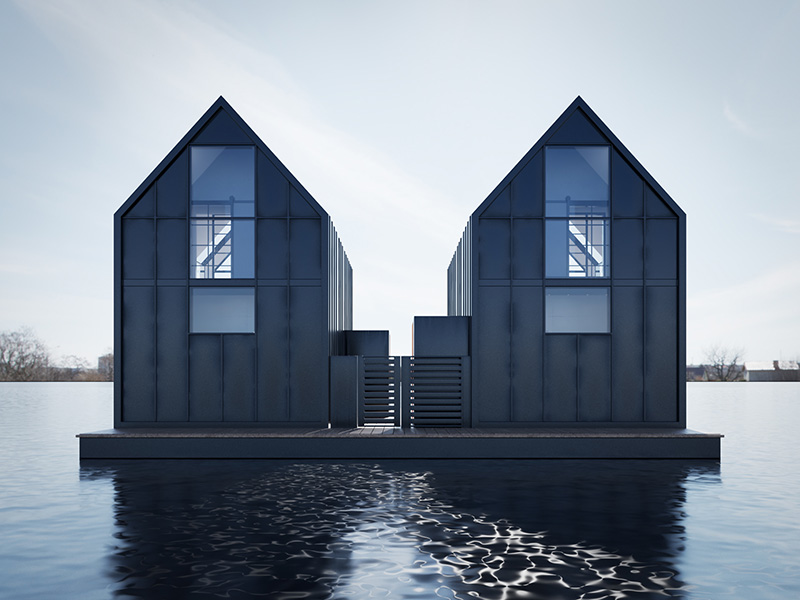

Since 2020, the company has also been involved in modular construction on water and designs floating houseboat buildings